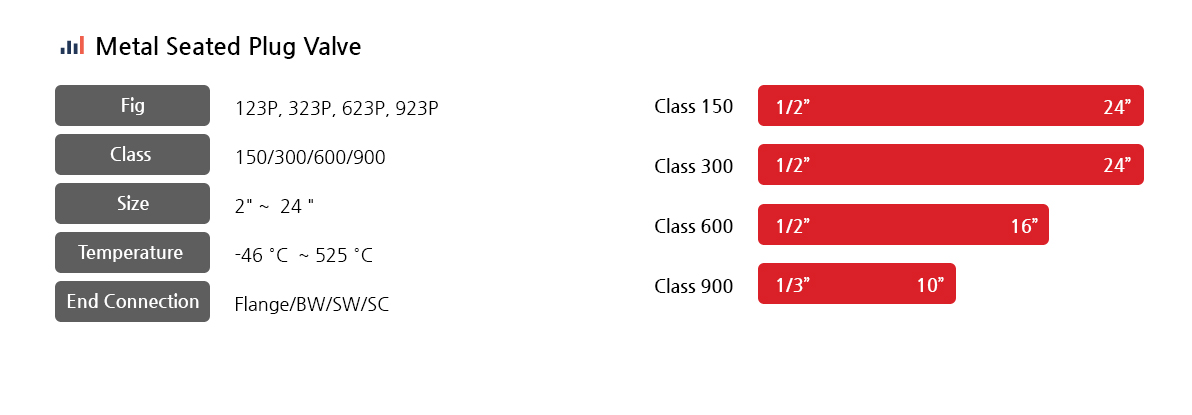

Metal Seated Plug Valve

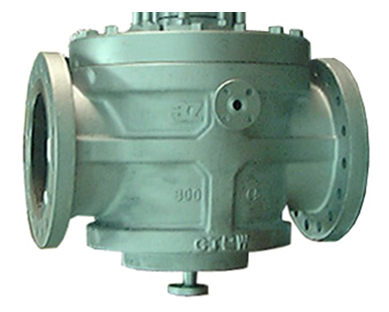

제품 이미지

Metal Seated Plug Valve

3Z Metal Seated Plug Valves

3Z metal seated plug valves are designed to be used for high or low temperature. The plug is contact with raised ribs of the body and create sealing surfaces. These sealing surfaces prevent line leakage, and also prevent stem leakage to assure no external leakage into the atmosphere.

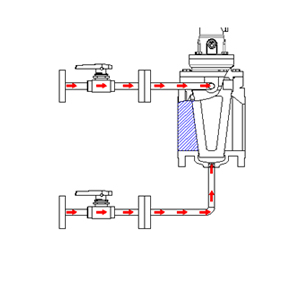

Mechanism(Operator)

Mechanism is very important part for this type of valve. Most of metal seated valve have high friction resulting in high torque. 3Z ball-locking mechanism make the plug away from body seat during opening and closing to provide low torque and smooth, frictionless operation.

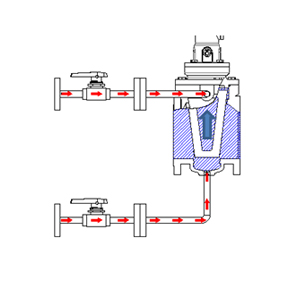

Purging Process

Whenever opening or closing the valve, the plug is lifted, rotated, lowered and seated. When the plug starts being lifted and rotated, purge media, which has higher pressure than line media is provided from the side and bottom port into the space between the body and plug for flushing inside of the valve.

When the plug is lowered and seated, the purging action stops automatically.

Therefore, the valve can be maintained clean inner surfaces and spaces.

-

STEP 1-PLUG CLOSED

-

STEP 2-PLUG LIFTING

-

STEP 3-PLUG ROTATING

-

STEP 4-PLUG OPENED

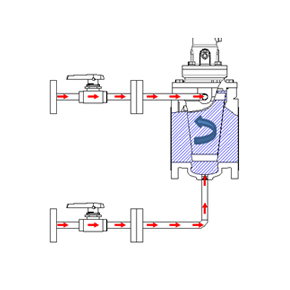

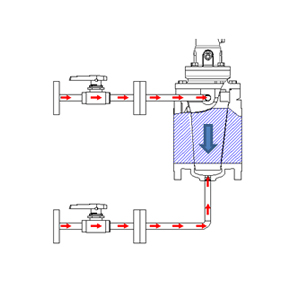

Jacketed Plug Valve

Jacketed Plug Valve: 3Z steam jacketed plug valves are designed to control special chemical service where media has to be required within a specified temperature range. The steam jacketed design prevents the media in the body from cooling down. If cool media become solid, the trim parts, plug and stem will be very hard to operate. The steam jacket keep maintaining required temperature of the valve.

Production Scope