Sleeved Plug Valve

제품 이미지

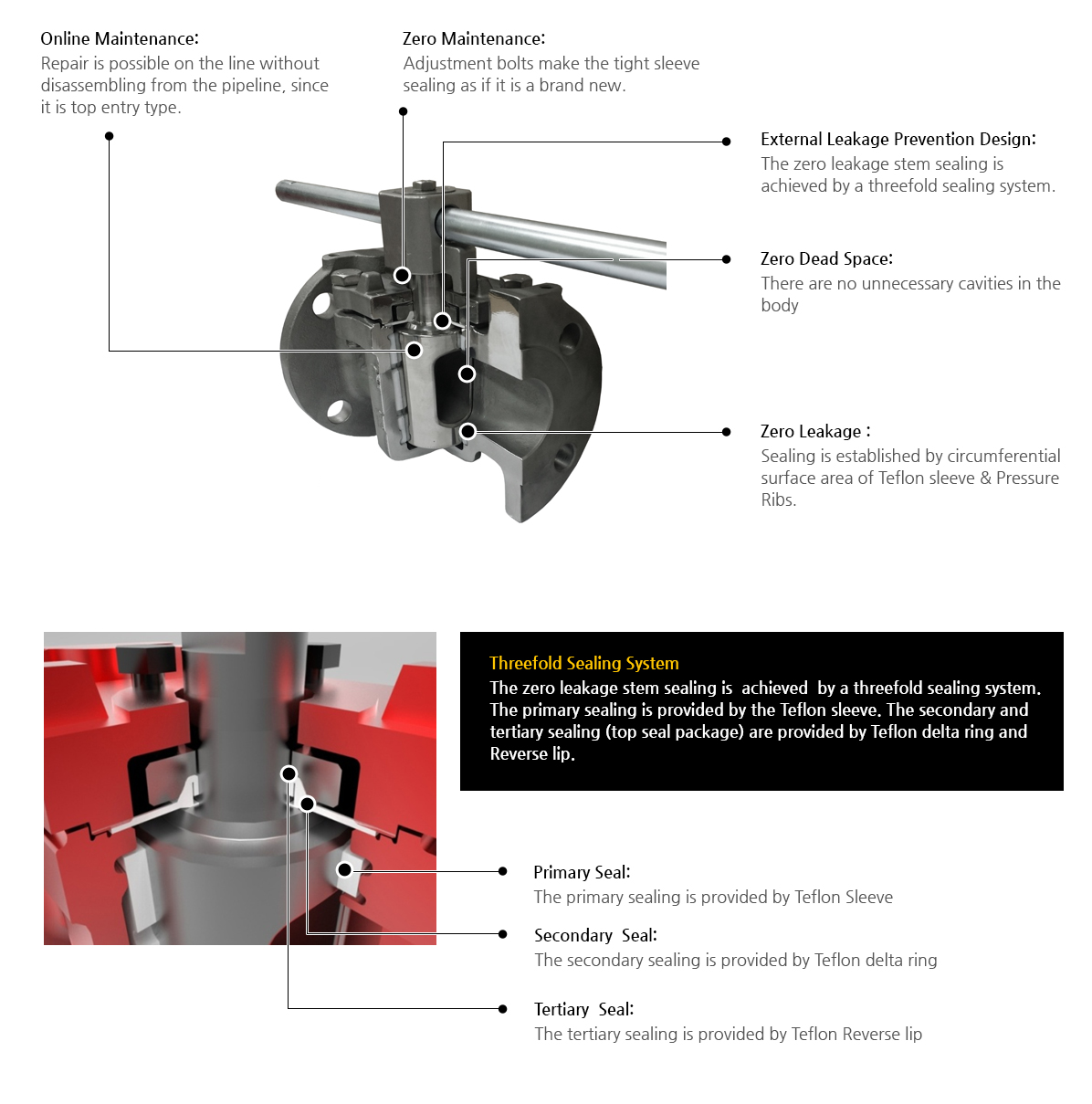

Sleeved Plug Valve

Fire Safety Design Top Seal:

Fire safety top seal is designed with the purpose of preventing external leakage. A graphite stem seal, flexible graphite cover seal and F.S metal diaphragm all prevent external leakage from fire.

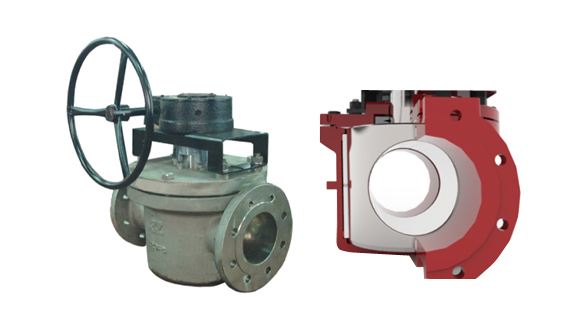

Sleeved Plug Valve – Kind of Products

-

Sleeved plug valve with wench

-

Sleeved plug valve with gear box

-

valve with pneumatic actuator

-

Full port sleeved plug valve

-

3way port sleeved plug valve

-

3way side port sleeved plug valve

-

Jacketed sleeved plug valve

-

Live loaded sleeved plug valve

-

Class 600 sleeved plug valve

-

Nuclear sleeved plug valve

-

Caged sleeved plug valve

-

Severe service sleeved plug valve

Sleeved Plug Valve

Multiport Plug Valves

Multiport valves are used in purpose of blending, diverting and segregation. It is more economical to use only one piece of 3-way valve instead of three pieces of 2-way valves. Multiport valves make piping simple and minimal.

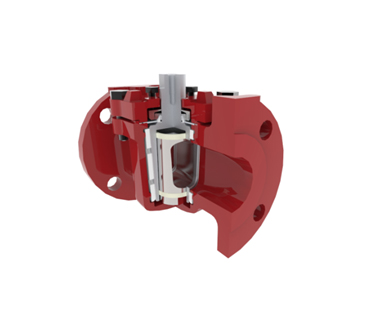

Full Port Plug Valves

There is no diminished flow with the full bore port, and also easy to pigging. For application such as high viscosity condensable media, high efficiency is demonstrated with full bore port.

Jacketed Plug Valve

3Z steam jacketed plug valves are designed to control special chemical service where media has to be required within a specified temperature range. The steam jacketed design prevents the media in the body from cooling down. If cool media become solid, the trim parts, plug and stem will be very hard to operate. The steam jacket keep maintaining required temperature of the valve.

Nuclear Plug Valve

Designed for nuclear power plant application. Standard Sleeve material is “UHMWPE”

- Port: 2-3 way

- Class: 150/300/600

- Size: 0.5“ - 6”

- Temperature Range: -29℃ ~ 100℃

Live loaded plug valves

Enhance stem sealing against external leakage by using live loaded disk spring and fugitive emission packing, and Live loaded plug valve is certified by ISO-15848(Industrial valves-Measurement, test and qualification procedures for fugitive Emissions)

High Pressure Plug Valve

3Z high pressure plug valves are designed for requirements of ASME B16.34 Class 600 and especially for 4” and over sized valves with top and bottom trunnion design. They securely operate against high differential pressure without excessive sleeve compression. 3Z high pressure plug valves are available in Reverse Osmosis (RO) Service.

Caged Plug Valve

3Z caged plug valves are designed for the requirements in throttling application and high pressure drops service. The cage fixed in the body protects sleeve from erosion during valve operation from open to close.

Severe service Plug Valve

3Z severe service plug valves are designed for maximum performance of external sealing . Especially the lantern ring between the top packing and the bottom packing provides an effective way to control the amount of stress in the packing set against packing wear and stem leakage.

Production Scope